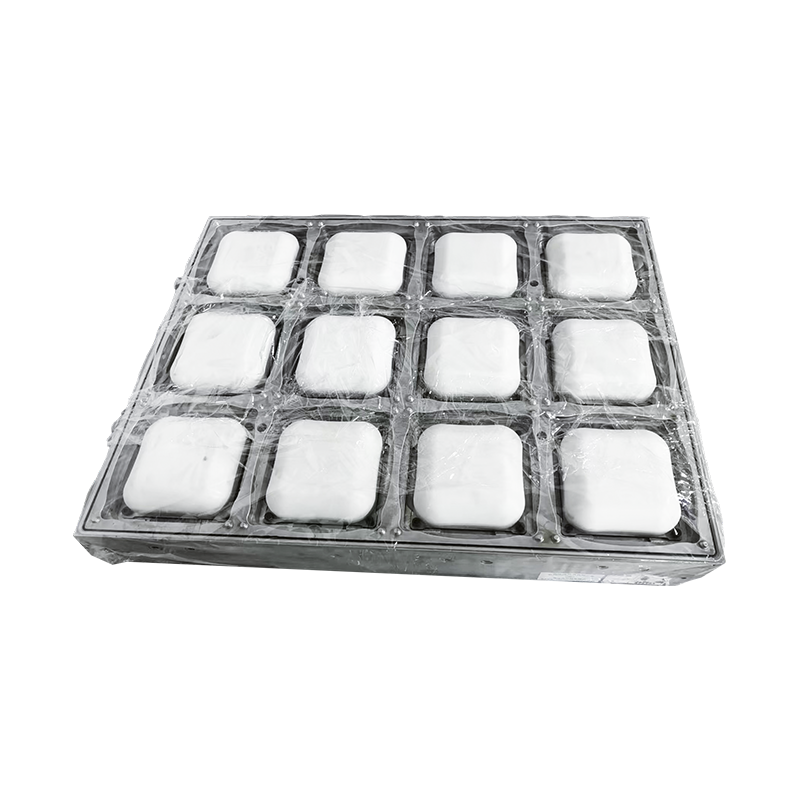

The food packaging industry is rapidly evolving, and plastic lunch box thermoforming molds are leading the way in innovation. These molds enable the mass production of high-quality containers that are functional, safe, and visually appealing for both consumers and commercial users.

Thermoforming involves heating plastic sheets and forming them over precision-engineered molds. This process produces lunch boxes that are uniform in shape and thickness, ensuring consistent quality across large production volumes. Plastic lunch box thermoforming molds also allow for multi-compartment designs, facilitating portion control and convenience for end-users.

Durability and safety are critical in food packaging. Thermoformed lunch boxes are typically made from FDA-approved materials that resist cracking, leaking, and deformation under normal use conditions. In addition, modern molds are designed for high efficiency, reducing cycle time, material waste, and overall production costs.

Environmental responsibility is shaping the future of thermoformed packaging. Many manufacturers are now adopting recyclable plastics or bio-based alternatives to meet sustainability goals. The precision and efficiency of thermoforming molds also minimize waste, making them a preferred choice for eco-conscious production lines.

FAQ:

-

Why are thermoforming molds preferred for lunch box production?

They provide high precision, fast production, and minimal material waste. -

Can thermoforming molds produce complex multi-compartment lunch boxes?

Yes, molds can be designed to create intricate designs with multiple compartments. -

Do thermoformed lunch boxes support large-scale production?

Absolutely, they are highly suitable for high-volume manufacturing while maintaining consistent quality.

English

English Español

Español عربى

عربى