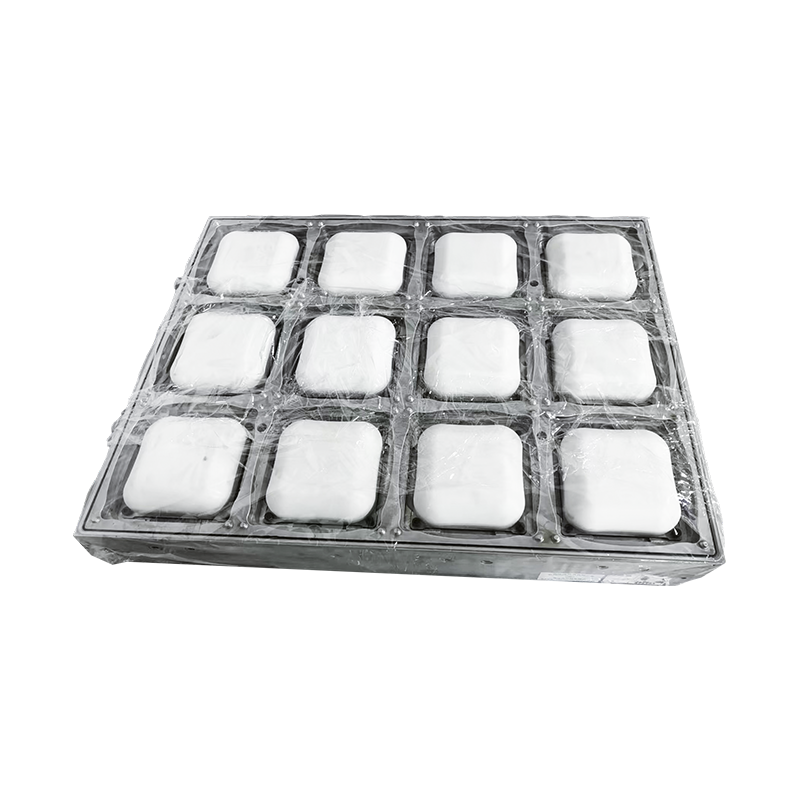

The global packaging industry is increasingly turning to thermoforming technology to meet the growing demand for efficient, cost-effective, and sustainable packaging solutions. With innovations in mold design and manufacturing processes, thermoforming molds—particularly for products like cup lids and plastic cups—are gaining traction across multiple sectors.

Suzhou Huashang Mould Co., Ltd., a leading manufacturer in the blister mold industry, is capitalizing on this trend by integrating advanced CNC machining and mold production technology into their operations. Established in 2005, the company has become a key player in thermoforming mold production, providing innovative solutions for blister packaging used in everything from food containers to medical devices.

The demand for precise and durable cup lid thermoforming molds is expected to rise significantly as industries shift towards sustainable materials and packaging solutions. Thermoforming molds allow for the creation of lightweight, cost-effective, and environmentally friendly products that reduce waste and enhance the consumer experience.

Huashang Mould’s expertise in blister design and manufacturing makes it uniquely positioned to take advantage of the growing market for cup thermoforming molds. With a skilled team of designers and over 18 CNC machining tools, the company can develop customized molds for a wide range of applications. This ability to create tailored solutions sets Huashang apart as a preferred partner for industries seeking high-quality thermoforming molds.

As consumers and manufacturers alike demand more environmentally friendly and sustainable packaging options, the role of thermoforming molds in the packaging landscape will continue to grow. Manufacturers like Huashang Mould are at the forefront of this evolution, offering cutting-edge solutions for cup lids and plastic cups, as well as other thermoformed products.

English

English Español

Español عربى

عربى