Product Description

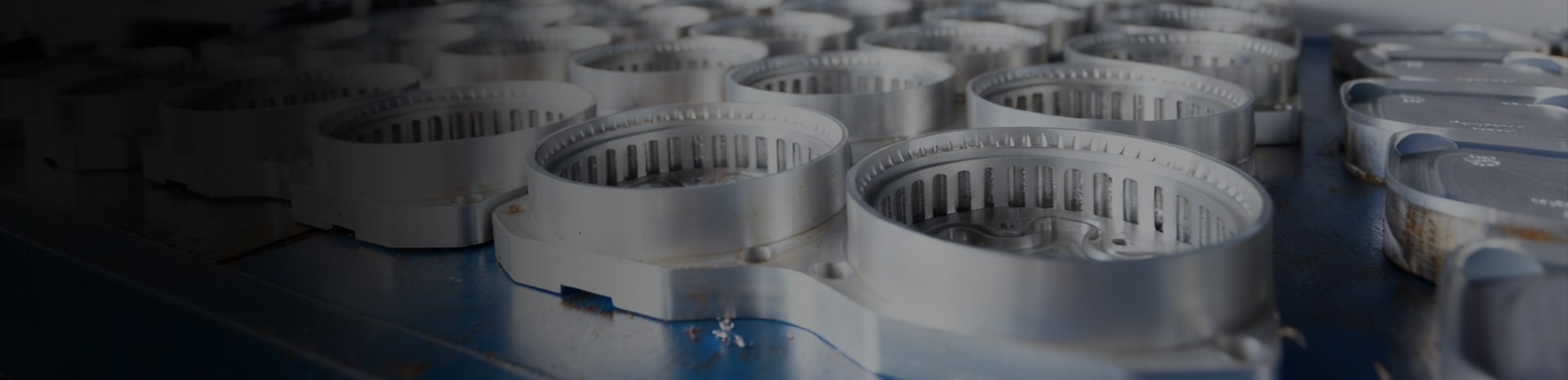

Round lidless packaging box thermoforming molds are widely used in the manufacture of plastic products such as disposable lunch boxes, salad bowls, dessert bowls, and takeout containers. Utilizing precise machining technology and scientific structural design, these molds achieve high molding efficiency, uniform wall thickness, and smooth demolding. They consistently produce round take-out boxes with standard dimensions, a smooth appearance, and high transparency. Made primarily of high-quality aluminum alloy, the molds undergo precision CNC machining and surface polishing, resulting in excellent thermal conductivity and wear resistance, ensuring stable molding results and a long service life during long-term production.

Round Lidless Packaging Box Thermoforming Mold

Product Features

Precise Structure: The mold cavity design is manufactured in strict accordance with product dimensional standards, ensuring the finished box has a high degree of roundness, smooth edges, and uniform thickness.

Excellent Thermal Conductivity: The mold is constructed of a highly thermally conductive metal material, with an optimized cooling channel layout, accelerating heat exchange and shortening molding cycles.

High Surface Finish: The mold's inner surface is finely polished or electroplated, resulting in a smooth, transparent surface for an enhanced visual effect.

Smooth Demolding: A well-designed demolding angle and vacuum suction mechanism effectively prevent mold sticking and deformation.

High Adaptability: Compatible with a variety of blister machines, including thermoforming of various materials such as PP, PET, PS, and PLA.

Easy Maintenance: The modular design allows for quick assembly and disassembly, reducing maintenance time and labor costs.

Application Scenarios

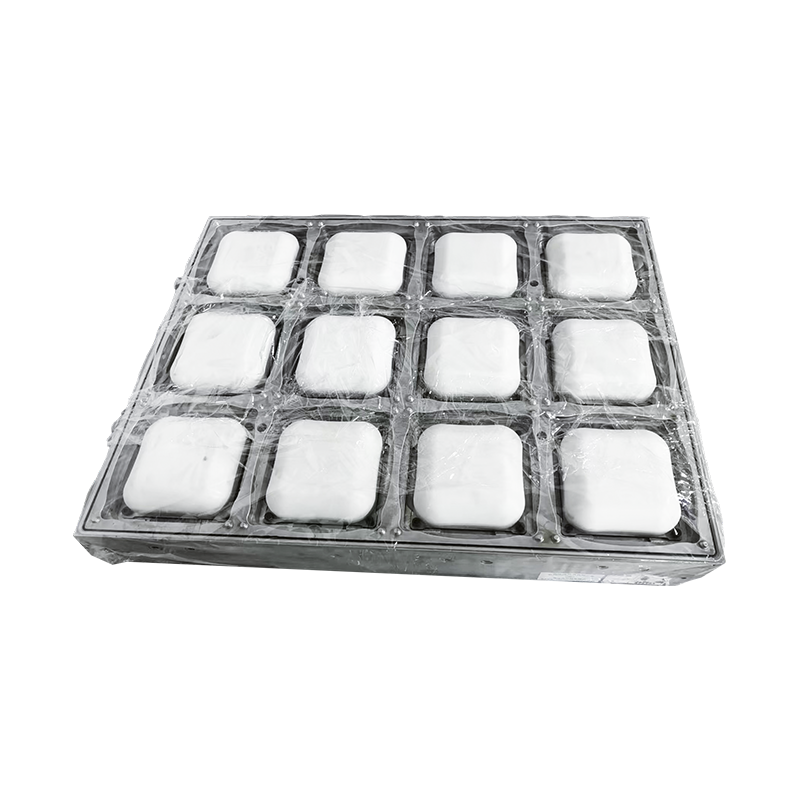

The round, lidless takeout containers produced by this mold are widely used in bakeries, dessert shops, fruit shops, supermarket prepared food sections, and takeout restaurants.

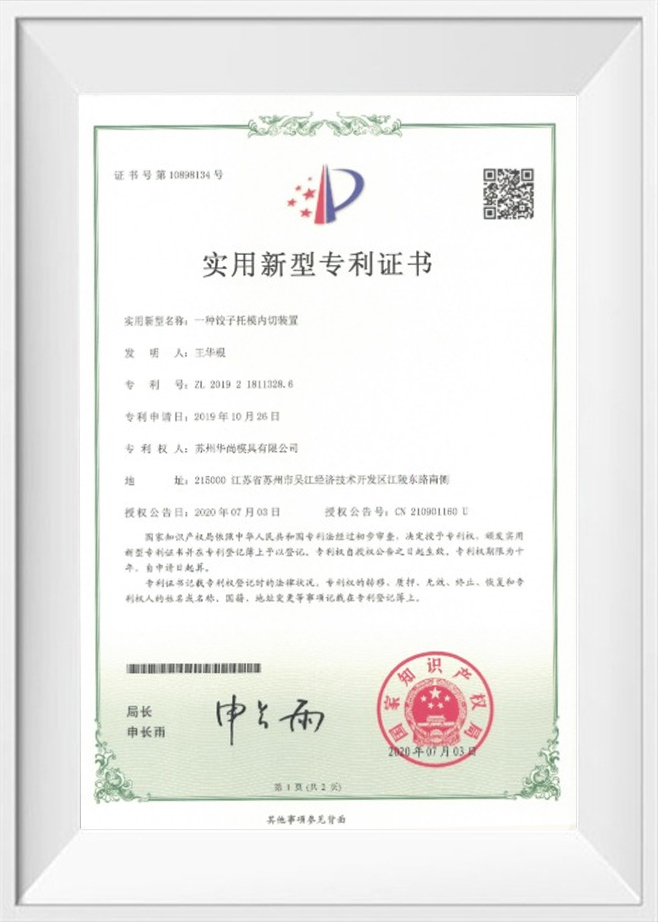

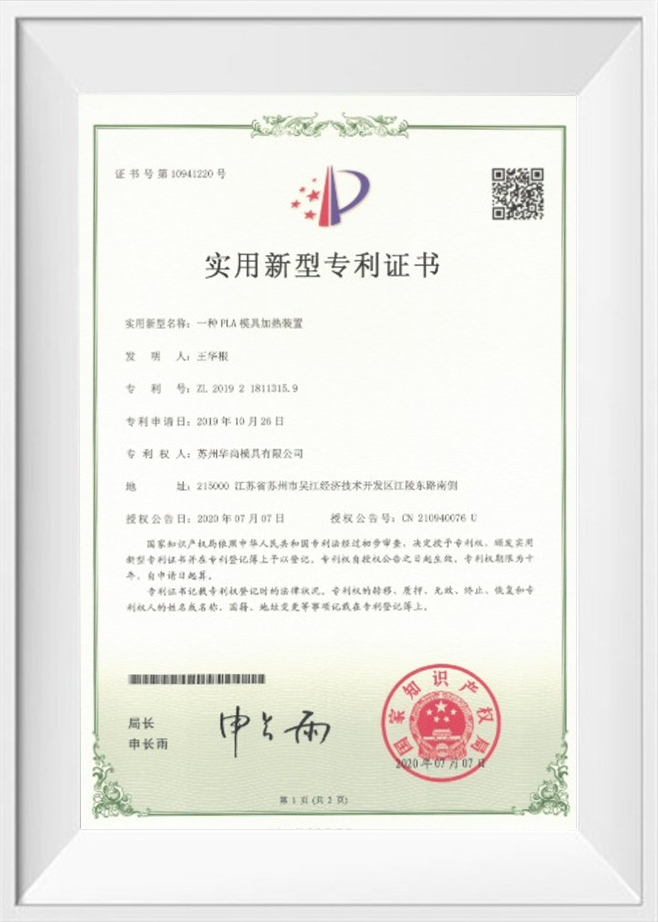

Suzhou Huashang Mould Co., Ltd. is China Customizable Round Lidless Packaging Box Thermoforming Mold Factory and Round Lidless Packaging Box Thermoforming Mold Suppliers. Our company specializes in producing domestic positive and negative pressure blister molds, large-scale positive and negative pressure blister molds for foreign markets, ordinary high-speed machine blister molds, ordinary single-head machine molds, domestic positive pressure blister molds, and large heat sink blister cooling plate molds (for Fortune 500 companies). Our blister molds are used in the food, electronics, automotive parts, toy, stationery, gardening, pharmaceutical, hardware, and cosmetic industries. We offer Round Lidless Packaging Box Thermoforming Mold for sale.

Our company consistently adheres to the business philosophy of "high quality, on-time delivery, excellent service, and reasonable prices," and continues to grow and develop. We will serve each customer with full enthusiasm, wholeheartedly serving those who have given us strong support and development, seizing every opportunity for development and cooperation, and striving to be the most trustworthy supplier of vacuum forming molds for our clients!

-

Product Introduction: What is a Rectangular Clamshell Packaging Box Thermoforming Mold? The rectangular clamshell packaging box thermoforming mold is a specialized mold used for producing rectangular, one-piece, lidded takeaway boxes. These molds are highly sought after in the food packaging industry, especially for ta...

READ MORE -

The demand for high-quality, customized thermoforming molds for cup lids and plastic cups is soaring, driven by advancements in manufacturing technologies and growing environmental concerns. These molds, which enable the production of a wide variety of packaging products, are playing an essential role in the evolution ...

READ MORE -

The global packaging industry is increasingly turning to thermoforming technology to meet the growing demand for efficient, cost-effective, and sustainable packaging solutions. With innovations in mold design and manufacturing processes, thermoforming molds—particularly for products like cup lids and plastic cups—are g...

READ MORE

English

English Español

Español عربى

عربى