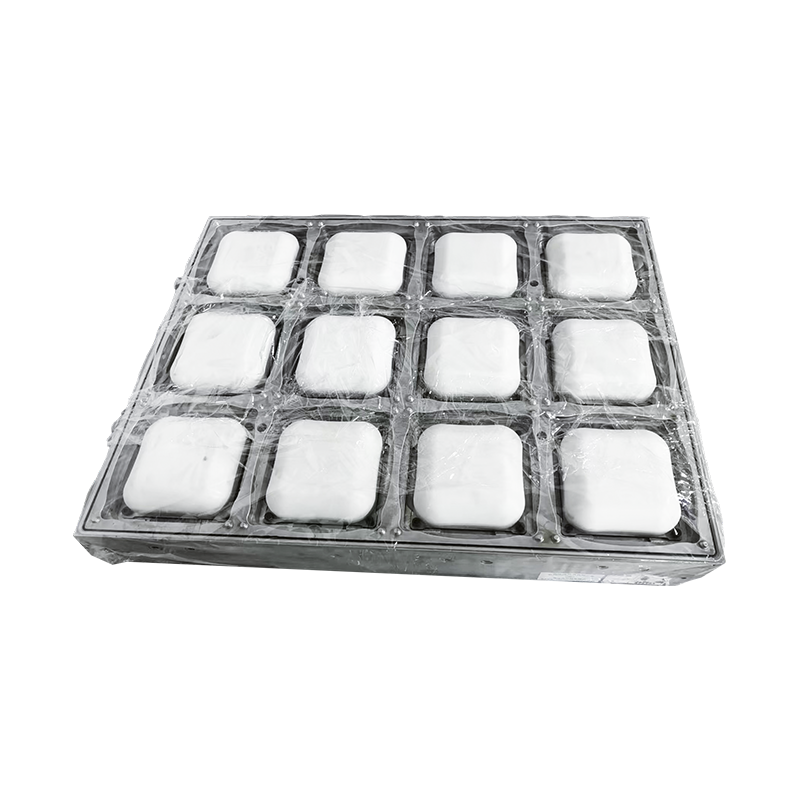

Product Introduction: What is a Rectangular Clamshell Packaging Box Thermoforming Mold?

The rectangular clamshell packaging box thermoforming mold is a specialized mold used for producing rectangular, one-piece, lidded takeaway boxes. These molds are highly sought after in the food packaging industry, especially for takeaway food, prepared meals, and various disposable eco-friendly containers. With the increasing demand for convenient, hygienic, and eco-conscious packaging, these molds provide the perfect solution.

Key Features and Advantages:

- High-Precision CNC Machining: The mold is made from high-quality aluminum alloy, machined with precision using CNC technology, ensuring high accuracy in production.

- Durability and Efficiency: The use of advanced alloy materials guarantees high production efficiency and a long lifespan, reducing overall manufacturing costs.

- Optimized Design: The mold cavity design and thermoforming structure are optimized for perfect sealing, uniform thickness, smooth edges, and excellent transparency.

- Versatility: These molds meet the practical requirements for packaging, ensuring products are not only functional but also aesthetically pleasing.

The ability of these molds to create consistent and durable packaging solutions makes them a popular choice in the packaging of food products, ranging from snacks to full meal containers. Additionally, they help maintain product freshness and hygiene during transportation and handling.

Thermoforming Technology Overview

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, stretched over a mold, and then cooled to create a solid structure. This technique is widely used in packaging applications due to its flexibility, cost-effectiveness, and high-quality results.

Thermoforming Process Steps:

- Heating the Plastic Sheet: The plastic sheet is first heated to a specific temperature at which it becomes soft and moldable.

- Forming the Shape: Once the plastic is pliable, it is stretched over the mold. A vacuum or pressure is used to force the plastic into the mold cavity.

- Cooling and Solidifying: The mold is cooled, and the plastic solidifies, taking the shape of the mold.

- Trimming: The excess plastic is trimmed away, leaving a well-formed package.

In the case of rectangular clamshell packaging box thermoforming molds, the process ensures that food packaging maintains high precision, smooth edges, and a perfect seal. This process is ideal for high-volume, high-quality production.

Advantages of Thermoforming:

- Cost-Effective: Thermoforming molds are relatively inexpensive to produce compared to other molding methods.

- Fast Production: Once the mold is ready, the thermoforming process can produce large quantities of products in a short amount of time.

- Customization: Thermoforming allows for customization in the size, design, and thickness of the packaging.

This makes thermoforming an attractive option for companies looking to create custom food packaging in a cost-efficient and timely manner.

Comparison of Different Mold Materials

Choosing the right material for thermoforming molds is crucial, as it affects the mold’s longevity, precision, and cost. Below, we compare the materials most commonly used for producing thermoforming molds: Aluminum Alloy, Steel, Copper Alloy, and Plastic.

Aluminum Alloy:

Aluminum alloy is a popular material choice for thermoforming molds due to its excellent machinability and lightweight properties. It is highly resistant to corrosion and offers superior thermal conductivity, which is essential for maintaining the temperature during the thermoforming process.

Advantages:

- High precision and smooth surface finish

- Lightweight, reducing transportation costs

- Excellent thermal conductivity

Disadvantages:

- Higher material cost compared to plastics

- Requires specialized CNC machining for high precision

Steel:

Steel molds are used for high-strength applications and are particularly suited for large-scale production runs. Steel offers greater durability and resistance to wear but is heavier and more expensive than aluminum.

Advantages:

- Highly durable, resistant to wear and tear

- Suitable for high-temperature environments

- Excellent for large production volumes

Disadvantages:

- Heavy and expensive

- Longer lead times due to more complex machining requirements

Copper Alloy:

Copper alloys are used in molds that require rapid heat dissipation. They are ideal for applications where temperature control is critical.

Advantages:

- Excellent thermal conductivity, allowing for faster cooling

- Can improve overall molding efficiency

Disadvantages:

- Expensive

- Softer than aluminum and steel, making them less durable in high-wear applications

Plastic:

Plastic molds are cheaper to produce but are usually limited to small-batch production or low-strength applications. While they are useful for prototypes or low-cost runs, they are not suitable for high-volume production.

Advantages:

- Low cost, easy to prototype

- Suitable for small runs

Disadvantages:

- Not durable enough for high-stress applications

- Limited precision and material handling capacity

Mold Material Comparison Table

| Material | Advantages | Disadvantages | Best Suited For |

|---|---|---|---|

| Aluminum Alloy | High precision, lightweight, excellent thermal conductivity, long lifespan | Higher material cost, specialized machining required | High-precision, high-volume production |

| Steel | Extremely durable, can handle large volumes and high temperatures | Heavier, more expensive, longer lead times | High-demand, heavy-duty applications |

| Copper Alloy | Excellent thermal conductivity, ideal for fast cooling | Expensive, softer material, lower durability | Specialized molds requiring fast cooling |

| Plastic | Low cost, easy to prototype, suitable for small runs | Low durability, limited precision, not for high temperatures | Low-cost production runs, experimental molds |

Customization and Technological Innovation in Thermoforming Molds

One of the greatest advantages of thermoforming is the ability to create customized molds to meet specific product requirements. Customization in mold design allows manufacturers to produce packaging solutions that cater to unique product shapes, sizes, and material properties.

Custom Thermoforming Mold Design:

- Tailored for Specific Products: Thermoforming molds can be fully customized to accommodate a wide range of product types, from food containers to consumer goods.

- Improved Production Efficiency: Custom molds are designed to optimize the production process, ensuring faster cycles and higher-quality outputs.

- Material Optimization: Designers can choose the best material for the mold based on the specific requirements of the product being packaged.

Technological advancements, such as Computer-Aided Design (CAD) and 3D printing, have made custom mold production more precise and efficient. These innovations allow for faster prototyping and the creation of complex designs that would have been challenging or impossible to produce with traditional methods.

Maintenance and Cleaning: How to Care for Thermoforming Molds

Proper maintenance and cleaning are essential to ensuring the longevity and efficiency of thermoforming molds. Without regular upkeep, molds can accumulate plastic residue, rust, or wear down over time, leading to poor quality in the finished products.

Cleaning the Mold:

- Use soft brushes or cloths to clean the mold surface, avoiding abrasive materials that could scratch or damage the mold.

- Regularly remove plastic residue or material leftover from the forming process.

- Avoid using harsh chemicals that could damage the mold’s surface.

Lubrication:

- Apply lubricants to moving parts of the mold to minimize friction and extend its lifespan.

- Use food-grade lubricants to ensure that the mold is safe for packaging food items.

Storage and Handling:

- Store molds in a dry, cool environment to prevent rust and corrosion, especially for steel and copper molds.

- Handle molds carefully to avoid damaging delicate parts, particularly those made from aluminum or copper alloys.

Product Applications

Thermoforming molds for rectangular clamshell packaging boxes have diverse applications across multiple industries, particularly in food packaging.

Food Packaging:

These molds are particularly popular for takeaway food containers and pre-packaged meal solutions. The rectangular clamshell design is ideal for holding various food types, from sandwiches to salads and snacks. The mold ensures the packaging is both practical and visually appealing.

Eco-Friendly Packaging:

As sustainability becomes more important to both consumers and businesses, the demand for eco-friendly packaging solutions has grown. These molds can produce containers made from biodegradable or recyclable materials, supporting the shift toward greener packaging options.

Other Applications:

Aside from food packaging, rectangular clamshell molds are used in packaging for consumer electronics, cosmetics, and household products. Their versatility makes them a go-to solution for any product requiring durable, secure packaging.

Comparison of Different Mold Shapes: Rectangular, Round, and More

Thermoforming molds come in a variety of shapes, each serving different packaging needs. Below is a comparison of the most common mold shapes used in the thermoforming industry.

Rectangular Molds:

-

Advantages: Efficient space utilization, easy to stack, and suitable for most food packaging applications.

-

Disadvantages: Limited flexibility for more intricate or unique product shapes.

Round Molds:

- Advantages: Ideal for specific products, such as beverage cans or round food containers.

- Disadvantages: Less efficient in space utilization, and harder to stack and store.

Custom Molds:

- Advantages: Fully tailored to meet unique packaging requirements.

- Disadvantages: More expensive and may have longer lead times due to the complexity of design.

Mold Shape Comparison Table

| Mold Shape | Advantages | Disadvantages | Best Suited For |

|---|---|---|---|

| Rectangular | Efficient space use, easy to stack, versatile | Limited design flexibility | Food packaging, takeaway containers |

| Round | Ideal for specific product shapes, aesthetic designs | Poor space efficiency, less stackable | Beverage cans, special packaging |

| Custom | Fully tailored design, highly flexible | Expensive, longer production times | Custom packaging, unique designs |

Conclusion

The rectangular clamshell packaging box thermoforming mold offers numerous advantages in both functionality and efficiency. With its ability to produce high-quality, eco-friendly packaging solutions, it is poised to play an increasingly important role in the packaging industry. Technological advancements and customization options ensure that this mold type can meet a wide range of product packaging needs while supporting sustainability.

FAQ

-

What materials are typically used for thermoforming molds?

Thermoforming molds are usually made from aluminum alloy, steel, copper alloys, or plastic, depending on the specific application. -

How do I maintain my thermoforming mold?

Regular cleaning, lubrication, and proper storage are crucial for maintaining your mold’s performance and longevity. -

Can thermoforming molds be customized?

Yes, thermoforming molds can be fully customized to fit specific design and material needs, ensuring the highest level of efficiency and precision. -

What are the environmental benefits of using thermoformed packaging?

Thermoformed packaging can be made from recyclable or biodegradable materials, reducing environmental impact compared to traditional packaging. -

How do rectangular molds compare to round molds?

Rectangular molds are more space-efficient and better suited for everyday food packaging, while round molds are used for specialized products like beverage cans.

English

English Español

Español عربى

عربى