In the dynamic world of packaging, efficiency, cost-effectiveness, and product presentation are paramount. The Round Lidless Packaging Box Thermoforming Mold stands as a critical tool in creating seamless, attractive, and functional packaging solutions for a myriad of industries, from cosmetics to electronics. Choosing the correct mold is not merely a purchase; it's an investment in your production line's speed, output quality, and overall profitability. A well-designed mold ensures precise forming, minimizes material waste, and withstands the rigors of high-volume production. This guide delves deep into the technical considerations, design nuances, and economic factors involved in selecting and optimizing these specialized molds, empowering you to make an informed decision that aligns with your specific packaging needs and business goals.

Core Concept: Understanding the Round Lidless Packaging Box Thermoforming Mold

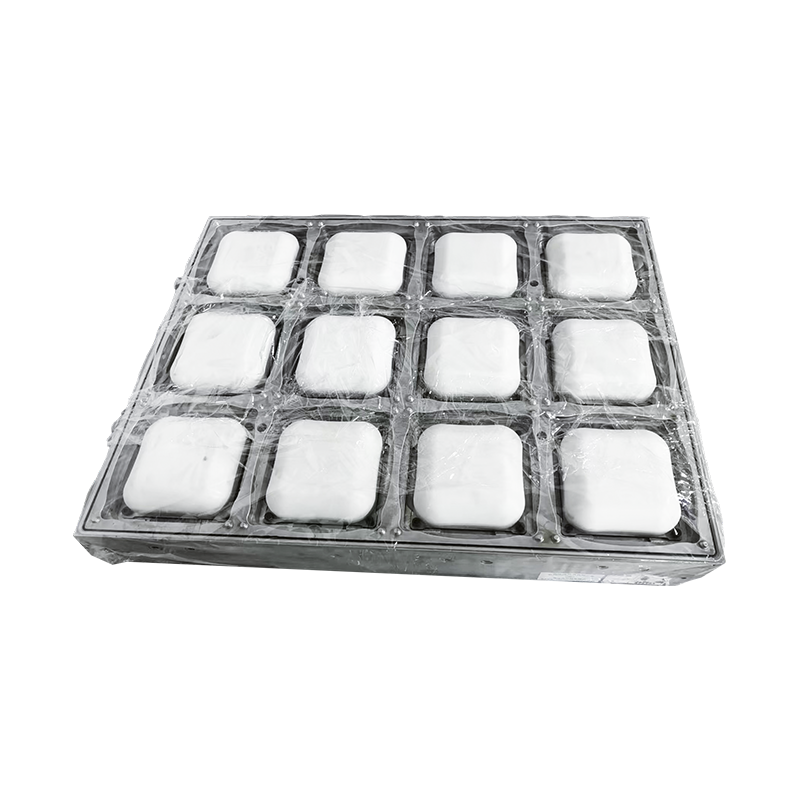

At its essence, a thermoforming mold is a precision tool used to shape heated plastic sheets into specific forms. A Round Lidless Packaging Box Thermoforming Mold is specifically engineered to produce round containers without an integrated lid, often used as base trays, insert holders, or standalone packages. This design is favored for its simplicity, stackability, and modern aesthetic. The "lidless" aspect is crucial; it means the mold's cavity is designed to form a single, open-top component, which may later be paired with a separate lid or sealing film. The engineering behind such a mold focuses on achieving sharp definition, uniform wall thickness, and easy part ejection, all while ensuring the final product meets exact dimensional tolerances for consistent filling and sealing on automated lines.

- Definition: A precision-machined tool, typically made from aluminum or steel, used in a thermoforming machine to mass-produce round, open-top plastic packaging containers.

- Key Advantage - Versatility: The round shape is universally appealing and functional, suitable for housing a wide range of products from cosmetic compacts to food items and electronic components.

- Key Advantage - Efficiency: The lidless design often simplifies the molding process, can allow for faster cycle times, and reduces material usage compared to more complex lidded clamshell designs.

- Production Context: These molds are central to creating plastic round box thermoforming mold design outputs, which prioritize both aesthetic form and manufacturing function.

From Design to Production: Five Key Steps to a Perfect Mold

The journey from concept to a functioning high-speed production round lidless packaging mold is a meticulous process that blends artistic design with rigorous engineering. Skipping or rushing any step can lead to costly defects, production downtime, and subpar packaging. It begins with a deep understanding of the end-use requirements and flows through detailed design, material selection, machining, and thorough testing. Each phase requires close collaboration between the client and the mold manufacturer to ensure the final tool not only creates the desired shape but also integrates seamlessly into the existing production environment, maximizing throughput and longevity.

Step 1: In-Depth Requirement Analysis & Planning for a custom round thermoforming mold for lidless boxes

This foundational step determines the project's trajectory. It involves gathering all specifications: the exact dimensions (diameter, depth, draft angles), required material (PET, PS, PP, PVC), expected production volume, and the type of thermoforming machine it will be used on (positive pressure, negative pressure, twin-sheet). Understanding the product to be packaged is vital—does it require friction fit, need ventilation holes, or have specific stacking requirements? This phase culminates in a detailed 3D model and project plan, ensuring both parties are aligned before any metal is cut.

- Client Consultation: Discuss product specs, annual volume, and aesthetic goals.

- Material Flow Analysis: Simulate how the plastic sheet will stretch and form into the mold cavity to predict wall thickness.

- Machine Compatibility Check: Confirm mold dimensions, plug assist requirements, and ejection system align with the client's forming equipment.

Step 2: Precision Engineering & plastic round box thermoforming mold design Essentials

The design phase transforms requirements into a manufacturable blueprint. Critical design elements for a round lidless box include draft angles (typically 3-5 degrees) for easy part release, radiused corners to prevent webbing and ensure structural integrity, and a meticulously planned cooling channel layout. For high-speed production round lidless packaging molds, efficient cooling is non-negotiable to reduce cycle time. The design must also account for venting (tiny holes to allow air escape) and may incorporate textured surfaces or polished finishes as required. Advanced CAD/CAM software is used to create tool paths for CNC machines.

- Draft Angle Optimization: Balancing ease of ejection against maintaining the desired visual profile.

- Cooling System Design: Engineering channels for water or oil to circulate close to the mold surface for uniform and rapid heat extraction.

- Ejection Mechanism: Designing pin locations or air ejection ports that won't mar the visible surface of the finished box.

Step 3: Material Selection: Impact on Performance and Durability

The choice of mold material is a critical trade-off between cost, performance, and lifespan. Aluminum is the most common choice for affordable thermoform mold for round containers due to its excellent thermal conductivity, lighter weight, and easier machinability. It's ideal for medium to high-volume production. For ultra-high-volume runs (tens of millions of cycles) or when forming abrasive materials, hardened steel or copper alloys may be used for their superior wear resistance, though at a higher initial cost and with slower cooling properties.

| Material | Best For | Key Advantage | Consideration |

| Aluminum (e.g., 6061-T6) | Most common; medium to high-volume | Excellent thermal conductivity, lightweight, cost-effective | Softer than steel, can wear over extreme cycles |

| Pre-Hardened Steel (e.g., P20) | High-volume, long-running production | High durability and wear resistance | Higher cost, heavier, lower thermal conductivity |

| Copper Alloys | Extreme high-speed cycles where cooling is paramount | Superior thermal conductivity | Very high cost, softer, requires protective plating |

Step 4: Optimization Strategies for high-speed production round lidless packaging mold

Speed is revenue in packaging production. Optimizing a mold for high-speed operation goes beyond just good design. It involves implementing conformal cooling channels (channels that follow the contour of the mold cavity for even cooling), using high-efficiency thermal coatings, and ensuring perfect balance on the machine platen. The goal is to minimize the "cooling time" phase of the cycle, which is often the longest segment. Additionally, automated ejection and part removal systems should be integrated into the mold design to facilitate seamless integration with robotics or conveyor systems.

- Conformal Cooling: 3D-printed or specially machined channels that provide uniform cooling, reducing warp and cycle time.

- Surface Treatments: Non-stick coatings (e.g., PTFE) to improve release and reduce cleaning downtime.

- Structural Rigidity: Ensuring the mold frame is robust enough to handle rapid, repeated clamping forces without deflection.

Step 5: Rigorous Testing and Final Validation

Before shipping, a reputable manufacturer will conduct sample runs. This involves mounting the finished mold in a thermoforming machine, running production-grade material, and producing sample parts. These parts are measured against all specified tolerances, checked for visual defects (like gloss variation or webbing), and tested for functionality (e.g., does the round box fit its intended lid or outer packaging?). Any necessary adjustments are made at this stage. This step is the ultimate guarantee that the custom round thermoforming mold for lidless boxes will perform as expected in the client's facility.

Cost Control: How to Find an affordable thermoform mold for round containers?

While quality should never be sacrificed, finding a cost-effective mold solution is a primary concern for many businesses. An affordable thermoform mold for round containers is not necessarily the cheapest one, but the one that offers the best total cost of ownership (TCO). This considers the initial tooling investment, its durability (avoiding frequent repairs or replacements), its production efficiency (saving on cycle time and material scrap), and the quality of parts it produces (reducing rejection rates). Strategic choices in the design and specification phase have the most significant impact on controlling upfront costs without compromising long-term value.

- Factor 1: Complexity: Simplify where possible. Every additional undercut, side-action, or complex texture increases machining time and cost.

- Factor 2: Material Choice: As detailed above, aluminum is typically the most cost-effective balance for many applications.

- Factor 3: Manufacturer Expertise: Partnering with an experienced manufacturer like Suzhou Huashang Mould Co., Ltd. can prevent costly design errors. With 18 CNC machines and a team of 8 professional designers, they streamline the process from design to finished tool, ensuring efficiency that controls cost.

- Factor 4: Standardization: Using standard mold base sizes and components whenever possible reduces custom machining costs.

Industry Focus: The thermoforming mold for round cosmetic packaging box

The cosmetics industry presents unique challenges and opportunities for mold design. A thermoforming mold for round cosmetic packaging box must produce parts that are not just functional but also exude luxury and brand identity. Surface finish is critical—often requiring a high-gloss polish or a specific matte texture. Dimensional precision is paramount to ensure secure fitting of powders, creams, or compacts. Furthermore, these molds may need to form specialized materials like acrylics or bio-plastics that have different thermal and forming characteristics than standard packaging plastics. The trend towards sustainability also drives demand for molds that can work efficiently with recycled content materials without sacrificing finish quality.

- High-Aesthetic Demands: Mirror finishes, precise radii, and flawless surfaces are non-negotiable for brand perception.

- Material Expertise: Experience with a wide range of plastics, including clear PET for visibility and ABS for painted finishes, is essential.

- Innovation Driver: The cosmetics sector often leads in adopting new mold technologies for unique effects, such as dual-texture surfaces or integrated hinges for separate lids.

Suzhou Huashang Mould Co., Ltd., with its focus on serving industries from cosmetics to pharmaceuticals, understands these nuanced requirements. Their integrated approach—combining design, manufacturing, and process improvement—ensures that a thermoforming mold for round cosmetic packaging box is engineered for both beauty and reliability on the production line.

FAQ

What is the typical lead time for a custom round lidless packaging thermoforming mold?

The lead time for a custom round thermoforming mold for lidless boxes typically ranges from 4 to 8 weeks, depending on the complexity, size, and current workload of the manufacturer. A simple, single-cavity aluminum mold can be on the faster end, while a multi-cavity, high-precision mold with conformal cooling for high-speed production will require more extensive engineering and machining time. It's crucial to discuss timelines upfront and include design approval and sample testing phases in the project schedule. An experienced supplier with substantial in-house CNC capacity, like a facility with 18 machines, can often offer more predictable and efficient turnaround times.

How can I maintain and extend the lifespan of my thermoforming mold?

Proper maintenance is key to protecting your investment in a Round Lidless Packaging Box Thermoforming Mold. Regular cleaning to remove plastic residue and degradation products prevents buildup that can affect part quality and damage the mold surface. Inspecting and cleaning water lines to prevent clogging and corrosion is vital for maintaining consistent cooling performance. Applying appropriate mold release agents sparingly can reduce wear. For aluminum molds, periodic inspection for nicks or wear on sealing surfaces and ejector holes is recommended. Storing molds in a dry, climate-controlled environment with protective coatings prevents oxidation. Following the manufacturer's specific maintenance guidelines will maximize the mold's operational life, ensuring it remains an affordable thermoform mold in the long run by avoiding premature failure.

Can I get a custom mold solution for a low-volume or prototype production run?

Absolutely. Many manufacturers, including Suzhou Huashang Mould Co., Ltd., offer solutions tailored to lower-volume needs. For prototypes or very short runs, a less expensive prototype-grade aluminum or even composite mold might be suitable. For small to medium production runs, a well-made aluminum production mold is still the best choice, as its per-part cost over the mold's lifetime makes it economical. The key is to communicate your projected volumes honestly. A reputable supplier will advise on the most cost-effective approach—whether it's a simplified plastic round box thermoforming mold design or using a single-cavity instead of a multi-cavity tool—to meet your quality requirements without over-investing in tooling built for millions of cycles.

English

English Español

Español عربى

عربى